14 advantages of the Herbert Phillips Mach 2 Waterjet Cutter

Important factors in guaranteeing you get the best cutting service and results.

Cost Effective – water jet cutting is cheaper than other processes.

All Materials – waterjet cuts all materials.

Thickness – waterjet cuts very thin materials and materials over 10’’ thick.

Creative – can cut intricately detailed patterns / shapes.

Accuracy – waterjet cutting can produce part accuracies better than 0.002″

Quality Finish – leaves a super-smooth finish, reducing the requirement for additional finishing.

No Material Damage – waterjet cutting doesn’t heat the material and therefore avoids causing heat damage or micro fracturing.

No Material Stress – zero stresses means zero damage.

Square Edges – can produce cut edge squareness < 1 degree.

Minimal Kerf Widths – waterjet cutting achieves minimal kerf widths (0.025″ to 0.050″).

Will Cut Composites – will cut various material types glued together.

Few Restrictions – there are no material thickness-to-hole diameter ratio restrictions.

Environmentally Friendly – waterjet cutting uses less energy and does not pollute the immediate environment.

Safe to Watch – while-you-wait customers can watch the Herbert Phillips Mach 2 in action.

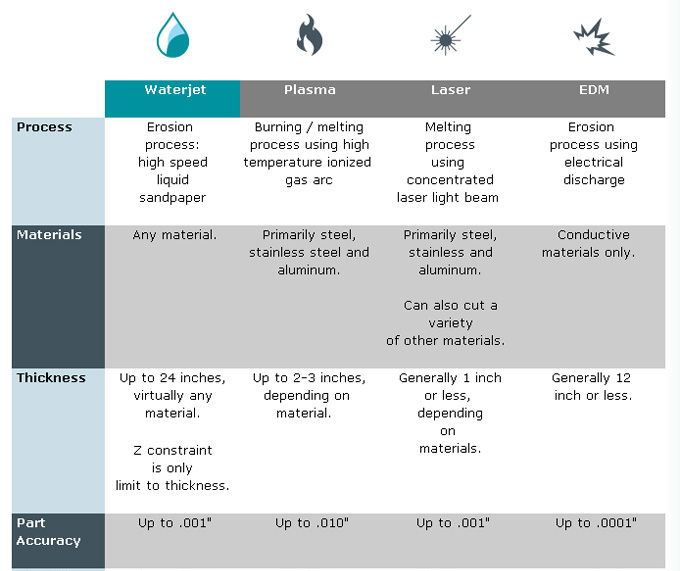

Waterjet Cutting Vs Other Methods

This comparison chart is reproduced with kind permission from www.flowwaterjet.com