Herbert Phillips Waterjet Cutting Services |

||

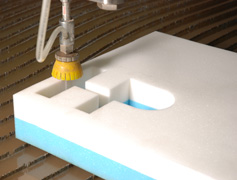

Our Mach 2 waterjet cutter based at our unit in Toddington, Cheltenham Gloucestershire is able to cut detailed patterns accurately in virtually any material up to a thickness of 150mm.The quality of the cut is so good that further machining processes can be eliminated thus saving your business money. Some of the materials the Mach 2 can cutCheck out some of the materials our Mach 2 waterjet cutter cuts with ease: Metal Advantages of Waterjet CuttingOur Mach 2 waterjet cutting service is better than other cutting services such as laser and plasma. Advantages of Waterjet Cutting Our ServicesHigh-Quality Results Fast – By focusing on lower-volume projects we are able to deliver high-quality, detailed jobs fast. We can also offer same-day turnaround for last-minute time-critical jobs. Excellent Customer Service – Andy and Stephen based at our Toddington site (Near Cheltenham Gloucestershire) are experienced at working with customers with exacting requirements. Being very customer-focused is not only our core principle; it comes as second nature to them. Andrew Jones and Stephen Williams have over 50 years of manufacturing experience between them including CAD/CAM. Operating the world's most powerful waterjet cutter the Mach 2 and state-of-the-art CAD/CAM software, Andrew and Stephen can provide you with a water jet cutting service that is second to none. Pre-Cutting ServicesAt Herbert Phillips, we firmly believe in the 6P rule – Perfect Preparation and Planning Prevents Poor Performance – which means that we now offer customers valuable pre-production advice and support. Collection - We regularity collect client materials from the Cheltenham, Gloucestershire, Worcestershire and Warwickshire areas. Design Review – we can review your design to ensure that it is the best possible solution for your requirements. Design Development – we can help you develop / improve your design (if required) Manufacture Design – using state-of-the-art CAD/CAM technology, we produce detailed accurate manufacturing designs – turning photos, sketches and drawings into CAD / DXF Source Top-Quality Materials – we can source the best materials at the best prices Supply Top Quality Materials – we work closely with some of the best materials suppliers both in and around Cheltenham, Gloucestershire and across the UK and can acquire top-quality materials at the best prices fast. Prototyping and Testing – if your project requires valuable or scarce materials, we can prototype and test on alternative materials prior to production. Cutting ServicesTake the Mach 2 – the world's most powerful waterjet cutter, add state-of-the-art CAD/CAM software and Andy and Stephen, two very experienced operators, and you have one of the best waterjet cutting services in the region. Diligence – your project will never be left unattended. Post Cutting ServicesWe not only provide customers with one of the best waterjet cutting services in the region; we also help customers improve quality, reduce costs and get the job done faster by providing the following post-cutting services: Polishing – Although our Mach 2 waterjet can produce smooth square edges and satin finishes, we can get the best polishing results via our reliable polishing partners. Painting – We can also arrange spray finishes or, for a superior finish, powder-coating where a super-tough enamel-like paint finish is achieved. Sourcing – With our extensive manufacturing experience and network of the best 'tried and tested' suppliers, we can source the additional materials and services required to complete your project. Manufacturing – We may be able to manufacture, either in house or via specialist partners, other key components required by your project. We have sheet metal work facilities, CNC milling machines, bespoke high-end metal furniture manufacturing and assembly teams and facilities, and a whole host of specialist manufacturing partners. Assembly – Whether additional parts are manufactured by us or supplied by you, we can assemble your project here at our factory or on site as part of our installation service. We have a have a team of experienced installers used to working in sensitive environments such as The Dorchester and the homes of discerning private clients. Delivery – We offer customers a delivery service using our own delivery teams and vehicles whenever possible so that you can rely on us to deliver your project in perfect condition. We regularity deliver to the Cheltenham, Gloucestershire, Worcestershire and Warwickshire areas. Your Next StepsFor more information about how our waterjet cutting services can deliver the best results for your project please contact Andy on 01242 621 090 or call in at our unit in Toddington, Cheltenham Gloucestershire. |

|

|

01242 621 090 or Request Callback